Slotting and product placement represent one of the most impactful yet often overlooked strategies for warehouse optimization, directly influencing picking productivity, travel time reduction, and overall operational efficiency. This systematic approach to determining optimal product locations within warehouse storage areas considers multiple factors including velocity analysis, product characteristics, order patterns, and ergonomic requirements. Effective slotting strategies can reduce picking travel time by up to 30% while improving order accuracy and worker safety, making it a critical component of successful warehouse management.

Understanding Velocity-Based Slotting

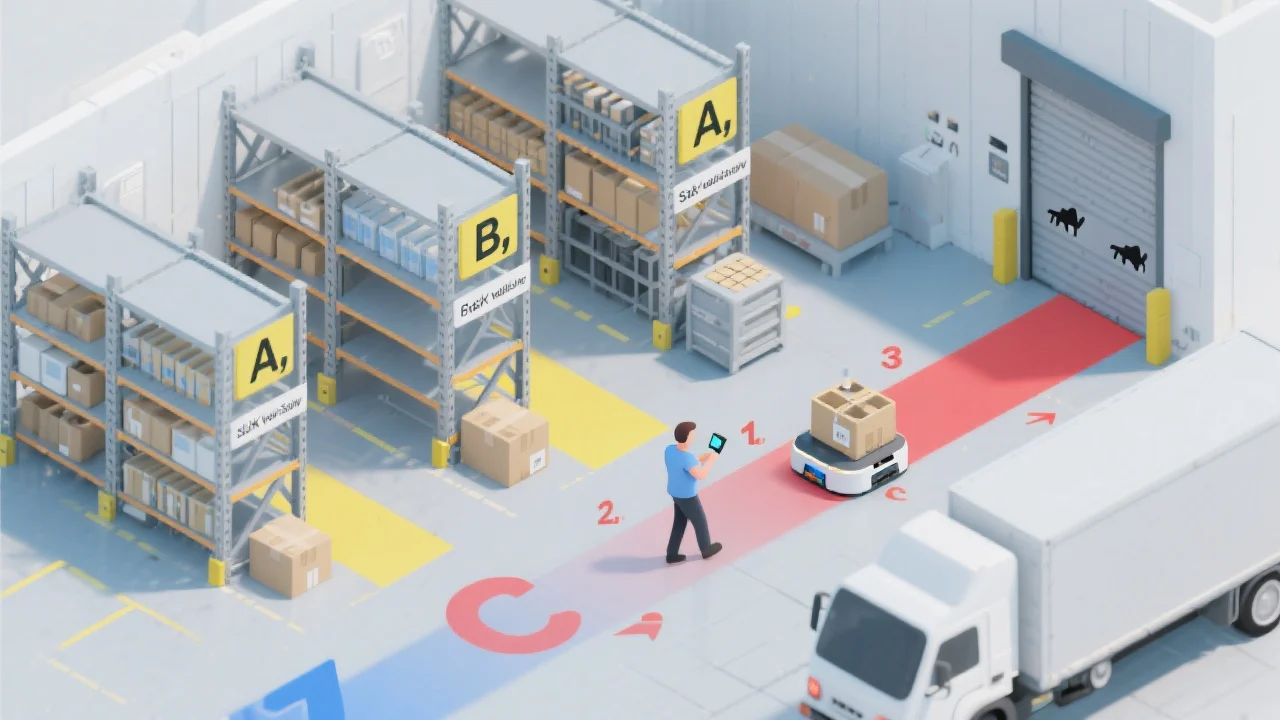

The foundation of effective slotting lies in velocity analysis, which categorizes products based on their frequency of movement and order volume. High-velocity items that are picked frequently should be located in the most accessible areas, typically in golden zones at waist height and close to shipping areas. Medium-velocity products occupy secondary locations that balance accessibility with space utilization, while slow-moving items are placed in less convenient but space-efficient locations.

ABC analysis provides a systematic framework for velocity classification, with A items representing the top 20% of products that typically account for 80% of picking activity. These products deserve prime real estate in the warehouse, positioned for maximum efficiency and minimal travel time. B items represent moderate movers that require balanced placement decisions, while C items are low-velocity products that can be stored in less accessible areas without significantly impacting overall productivity.

Seasonal variations add complexity to velocity-based slotting, as product movement patterns change throughout the year. Effective slotting strategies incorporate seasonal forecasts and adjust product locations accordingly. This may involve temporary relocations during peak seasons or maintaining flexible storage areas that can accommodate changing velocity patterns without major layout disruptions.

Physical Product Characteristics and Storage Requirements

Product dimensions, weight, and handling requirements significantly influence optimal placement decisions. Heavy items should be stored at appropriate heights to minimize lifting injuries and comply with ergonomic guidelines. Typically, items weighing more than 50 pounds should be stored below shoulder height, while lighter items can be placed in higher locations to maximize vertical space utilization.

Size compatibility ensures that products fit appropriately within designated storage locations without wasting space or creating handling difficulties. Oversized items may require specialized storage areas or equipment, while small items benefit from drawer systems or bin locations that prevent loss and improve picking accuracy. Cube utilization calculations help determine the most space-efficient storage configurations for different product categories.

Fragile products require special handling considerations and protective storage environments. These items should be located away from heavy traffic areas and positioned where they are less likely to be damaged by adjacent products or handling equipment. Environmental requirements such as temperature control or protection from moisture may dictate specific storage zones within the warehouse facility.

Order Pattern Analysis and Zone Optimization

Understanding order patterns enables strategic placement that minimizes travel time and improves picking efficiency. Products frequently ordered together should be located in close proximity to enable efficient batch picking and reduce travel between locations. This correlation analysis identifies product affinities that may not be obvious from individual velocity data but significantly impact overall picking performance.

Zone-based slotting strategies organize the warehouse into picking zones that align with order characteristics and operational workflows. Fast-pick zones contain high-velocity items in compact areas that enable rapid order fulfillment, while bulk storage zones handle larger quantities and slower-moving products. Cross-dock zones facilitate direct transfer operations, while value-added service areas support customization and packaging requirements.

Pick path optimization considers the sequence of product locations to minimize total travel distance for typical orders. Effective slotting arranges products along logical pick paths that follow natural traffic flow patterns and reduce backtracking. This may involve placing complementary products in sequence along pick aisles or organizing products by order priority to support wave-based picking strategies.

Technology Integration and Data-Driven Decisions

Modern slotting strategies leverage warehouse management systems and advanced analytics to make data-driven placement decisions. These systems analyze historical order data, track picking performance, and identify optimization opportunities that may not be apparent through manual analysis. Real-time data enables dynamic slotting adjustments that respond to changing product velocities and operational requirements.

Simulation software enables testing of different slotting scenarios before implementation, helping managers understand the potential impact of placement changes on overall performance. These tools can model various layouts, analyze travel distances, and predict productivity improvements from different slotting strategies. This analytical approach reduces the risk of implementing changes that may actually decrease efficiency.

Labor management systems track individual picker performance across different warehouse areas, providing insights into how product placement affects productivity. This data helps identify areas where slotting improvements could have the greatest impact and validates the effectiveness of placement changes after implementation.

Implementation and Continuous Improvement

Successful slotting implementation requires careful planning and change management to minimize operational disruption. Major slotting changes are typically implemented during low-activity periods and may be phased over time to maintain service levels. Clear communication with warehouse staff ensures understanding of new product locations and procedures.

Performance measurement systems track key metrics including picking productivity, travel time, order accuracy, and worker satisfaction. These measurements provide feedback on slotting effectiveness and identify areas for further improvement. Regular reviews of slotting performance ensure that the strategy continues to deliver benefits as business conditions change.

Continuous improvement processes regularly evaluate and update product placement based on changing business requirements, new product introductions, and operational feedback. This ongoing optimization ensures that slotting strategies remain effective and continue to support warehouse efficiency goals. Seasonal reviews, annual assessments, and event-driven updates maintain optimal product placement throughout changing business cycles.

Effective slotting and product placement represent fundamental warehouse management capabilities that directly impact operational efficiency, cost control, and customer service levels. Organizations that invest in systematic slotting strategies and maintain ongoing optimization efforts will achieve significant competitive advantages through improved productivity and reduced operational costs.