Cross-docking represents one of the most efficient strategies in modern warehouse logistics, fundamentally transforming how goods move through the supply chain. By facilitating the direct transfer of products from inbound to outbound transportation with minimal or no storage time, cross-docking operations eliminate traditional warehousing steps, accelerate delivery times, and significantly reduce handling costs. This lean approach to distribution has become increasingly vital as businesses seek to meet growing customer demands for faster delivery while maintaining cost-effective operations.

Understanding Cross-Docking Fundamentals

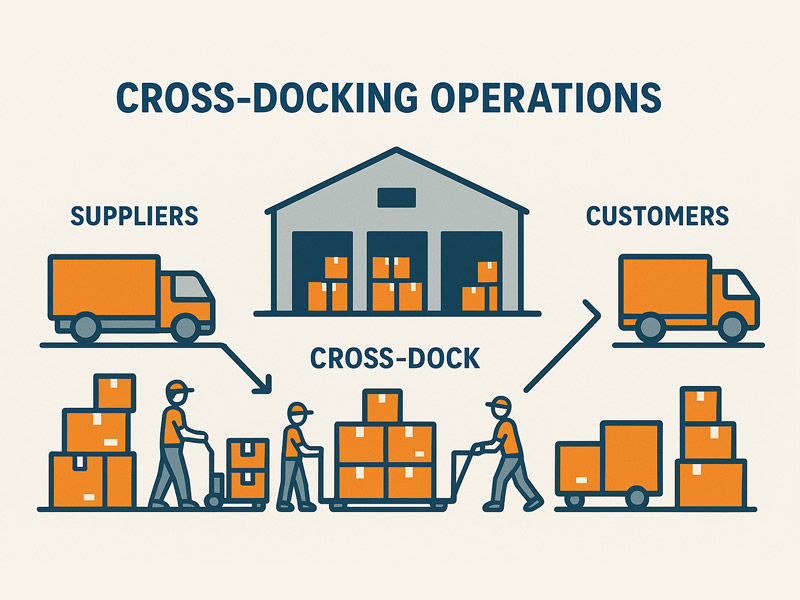

At its core, cross-docking is a logistics practice where products are received at a distribution facility and immediately prepared for shipment to customers or retail locations, bypassing traditional storage processes. The concept revolves around precise timing and coordination, with inbound shipments arriving just as outbound transportation becomes available. This synchronization requires sophisticated planning and execution capabilities that distinguish cross-docking operations from conventional warehouse activities.

The process typically occurs in specialized facilities designed with multiple dock doors positioned to facilitate smooth product flow. Inbound trucks deliver products to one side of the facility while outbound vehicles wait on the opposite side. Products are quickly sorted, consolidated, and transferred across the dock area, often within hours of arrival. This rapid throughput minimizes handling time and reduces the risk of damage or loss associated with multiple touches and extended storage periods.

Cross-docking operations can be categorized into several types based on the level of processing required. Pre-distributed cross-docking involves products that are already sorted and labeled for specific destinations, requiring minimal handling at the dock. Consolidation cross-docking combines smaller shipments from multiple suppliers into larger, more economical loads for final delivery. Manufacturing cross-docking receives components and parts that are quickly assembled or configured before immediate shipment to customers.

Strategic Advantages and Benefits

The primary advantage of cross-docking lies in its ability to dramatically reduce inventory carrying costs. By eliminating or minimizing storage time, businesses can reduce warehouse space requirements, lower inventory holding costs, and decrease the risk of obsolescence or spoilage. This is particularly valuable for perishable goods, fashion items, or technology products where time-to-market is critical for maintaining value and competitiveness.

Transportation efficiency improves significantly through cross-docking operations. Consolidating shipments from multiple suppliers enables better truck utilization and reduces the number of vehicles required for final delivery. This consolidation not only lowers transportation costs but also reduces environmental impact through improved fuel efficiency and reduced emissions. Additionally, the direct transfer process minimizes handling damage and reduces labor costs associated with put-away and picking activities.

Customer service benefits emerge from faster order fulfillment and improved delivery reliability. Cross-docking enables businesses to respond more quickly to demand fluctuations and rush orders, providing competitive advantages in markets where speed is valued. The reduced handling also improves product quality and reduces the likelihood of errors that can occur during traditional warehousing processes.

Operational Requirements and Challenges

Successful cross-docking operations demand exceptional coordination and timing precision. Suppliers must deliver products according to strict schedules, with any delays potentially disrupting the entire operation. This requires strong supplier relationships, reliable transportation providers, and robust communication systems to manage the complex choreography of inbound and outbound activities.

Information systems play a crucial role in cross-docking success. Advanced warehouse management systems must provide real-time visibility into inbound shipments, processing requirements, and outbound transportation schedules. These systems coordinate the various activities, optimize dock door assignments, and ensure that products are properly sorted and loaded onto the correct vehicles. Integration with supplier and carrier systems enables proactive management of potential disruptions.

Facility design considerations are paramount for effective cross-docking operations. The layout must facilitate smooth product flow while providing adequate space for sorting and temporary staging activities. Dock door configuration, interior circulation patterns, and material handling equipment must be optimized for rapid throughput. Many cross-docking facilities feature elevated dock platforms, conveyor systems, and automated sorting equipment to maximize efficiency.

Labor management presents unique challenges in cross-docking environments. Workers must be skilled in rapid sorting, quality checking, and loading activities while maintaining accuracy under time pressure. Flexible staffing models accommodate the variable workloads associated with scheduled shipment arrivals and departures. Cross-training ensures that employees can handle different types of products and processing requirements as demand fluctuates.

Technology Integration and Innovation

Modern cross-docking operations increasingly rely on advanced technologies to manage complexity and maintain efficiency. Radio frequency identification systems enable automatic tracking of products as they move through the facility, providing real-time visibility and reducing manual scanning requirements. These systems can automatically trigger sorting decisions and update inventory systems as products transfer between transportation modes.

Automated material handling equipment, including conveyor systems and robotic sorting technologies, can significantly improve throughput and accuracy in high-volume cross-docking operations. These systems can sort products by destination, consolidate shipments, and route items to appropriate loading areas with minimal human intervention. However, the investment in automation must be carefully balanced against volume requirements and operational flexibility needs.

Predictive analytics and artificial intelligence applications help optimize cross-docking operations by forecasting demand patterns, identifying optimal consolidation opportunities, and predicting potential disruptions. These tools enable proactive decision-making and can automatically adjust operational parameters to maintain efficiency as conditions change.

Industry Applications and Future Trends

Cross-docking has found particular success in retail distribution, where major retailers use these operations to efficiently distribute products from suppliers to store locations. The grocery industry leverages cross-docking for perishable goods distribution, minimizing storage time to maintain product freshness. E-commerce fulfillment increasingly incorporates cross-docking principles to accelerate delivery times and reduce costs.

The future of cross-docking operations will likely see continued integration with omnichannel distribution strategies, where facilities serve multiple channels simultaneously. Sustainability considerations will drive further optimization of transportation consolidation and energy-efficient facility designs. Advanced automation and artificial intelligence will enable more sophisticated decision-making and operational optimization.

Cross-docking represents a powerful strategy for businesses seeking to optimize their supply chain efficiency while meeting increasing customer expectations for speed and service. Success requires careful planning, robust technology systems, and strong partnerships throughout the supply chain, but the benefits of reduced costs, improved service, and enhanced competitiveness make cross-docking an increasingly attractive option for modern logistics operations.